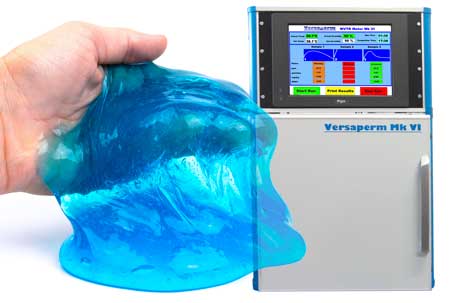

Versaperm Reveals Hidden Truths About Vapour Permeability in Sealants and O-Rings

Click

on the image to download a print quality scan

Versaperm, a UK leader in vapour permeability testing, is urging manufacturers and engineers to take a closer look at the materials and seals they rely on - because things are not always what they seem. A seal or O-ring that performs flawlessly against liquids may still be failing in a far more subtle and potentially damaging way when it comes to vapours.

It’s an easy trap to fall into. The instinctive assumption is that if a material or component can keep out water in its liquid form, then it must be doing its job. But water vapour is an entirely different story. Take silicone, for example - a widely used material prized for its liquid water resistance. While silicone makes an excellent liquid barrier, it is, in fact, a very poor barrier to water vapour. Similarly, cellulose, often found in packaging and composites, exhibits the same paradox. These, and other, materials appear effective but can allow significant quantities of vapour to pass through, often without any visible sign of failure.

This hidden permeability can have serious consequences. From pharmaceutical packaging and food preservation to electronics, aerospace and automotive applications, vapour ingress can lead to corrosion, reduced shelf life, contamination or mechanical failure. Even seals, screw caps, and joints that seem airtight can become less effective due to factors such as overtightening. Ironically, excessive force can deform or damage the sealing surfaces, increasing the pathways through which vapour can escape or enter.

Versaperm’s testing systems are designed specifically to detect and measure vapour permeability in finished components as well as material samples. They do this with precision and speed and the equipment can handle almost every vapour - including water, oxygen, hydrocarbons and hydrogen. The instruments offer sensitivity levels down to parts per million or even sometimes parts per billion, providing essential data that helps companies design more reliable and efficient products.

Chris Roberts, Managing Director at Versaperm, explains: “Vapour permeability is one of those things that is easy to overlook—until something goes wrong. It’s not about whether a seal looks good or feels tight, it’s about how it performs on a molecular level. That’s where our technology makes the difference.”

With applications across virtually every industry, Versaperm is helping companies uncover weaknesses they didn’t even know existed and to develop better solutions from the outset. In a world increasingly dependent on precision and performance, understanding vapour permeability is no longer optional - it’s essential.

As well as manufacturing and supplying high-precision permeability measurement equipment, Versaperm also offers laboratory testing and consultancy services.

ENDS

Please send

any sales enquiries to Christopher Roberts, Versaperm Limited,,

10 Rawcliffe House, Howarth Road, Maidenhead, Berkshire, SL6 1AP, UK, Tel: +44 (0) 1628 777668,

e.mail info@versaperm.co.uk

Web http://www.versaperm.co.uk

For further

Press Information please contact Gerry Palmer @

T the Palmer & Rose

Partnership.

Tel +44 (0) 1494 637499, e.mail gerry@palmer-rose.co.uk.

|